CUSTOM-MADE FORCE TRANSDUCERS

Specialised in the manufacture of custom-made force and torque transducers

SENSY offers a very wide range of standard force and torque sensors.

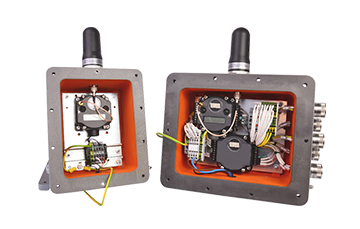

Nevertheless, in spite of this extensive choice, it is possible that there is not a model which is suitable for your application, because of the dimensions, the method of applying the force or the torque, the type of output signal, the environment, measurement of a combination of force and torque, or any other particular aspect (dynamic effects, parasitic stresses, extreme temperatures, conditions of use: subsea, corrosive, nuclear or mining environment, presence of gas with explosion risks, etc.).

This may require the slight adaptation of an existing load cell or the complete study of a new force transducer.

Since the company began, SENSY has made it a point of honour to keep enough flexibility to meet your specific demands, in order to provide you with the custom-made load cell that best suits your specifications while taking economic constraints into account. Sometimes the best solution is to turn a piece of the existing machine into a force sensor.

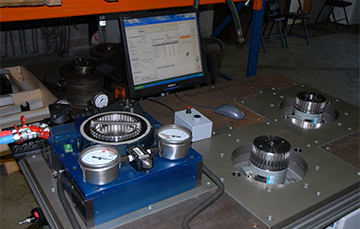

To do this, SENSY has a design and an electronics department, programmers and its own machine shop, all based in Belgium (Europe) and necessary for the efficient development of prototypes.

In addition, SENSY’s technical expertise can help in the design of your machine to define the best solution to integrate the force or torque measurement in your system.

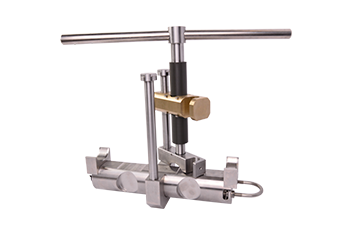

The most common requests in the manufacturing of custom-made load cells are:

Adaptability and flexibility

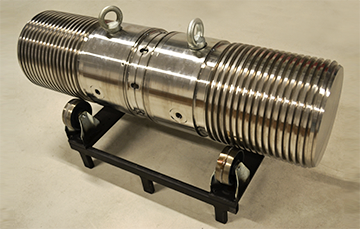

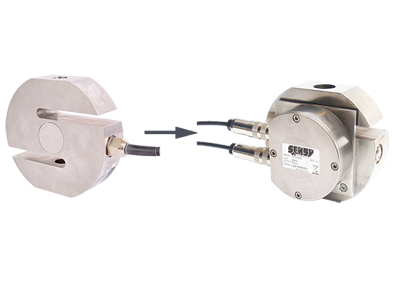

Non-standard connector or cable, double-bridge load cell, special thread, Specific surface treatment, …

SENSY offers a very wide range of standard force and torque transducers. Nevertheless, it is common to have to make specific changes to meet individual customer requests.

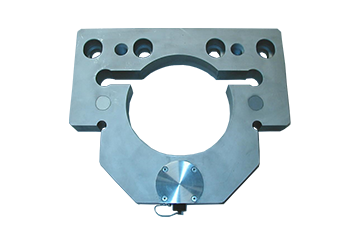

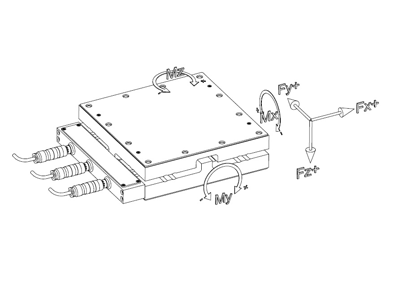

Multi-direction load cell (3 forces and the moments)

Analyse the different efforts and torques to which the seat and back of a wheelchair are subjected

From the customer specifications to the manufacturing, here is a good example of the progress of the different steps of load cells design.

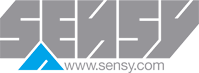

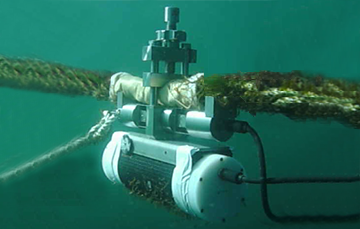

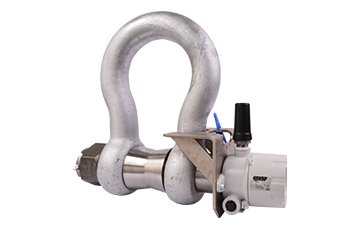

Tension measurement with a subsea load cell.

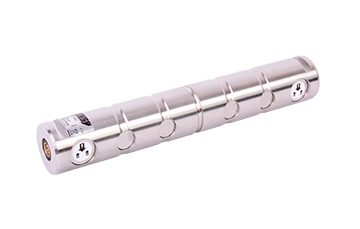

Immersible force sensors for a military application.

Needs analysis, development and manufacturing to design several load cells that will measure and display the tension forces applied to slings designed to hold a submarine launching ramp in place.