STANDARD REFERENCE TORQUE TRANSDUCERS

Since the relationship between the force applied to a torque meter and the electrical signal generated cannot be precisely determined by calculation, it is necessary to carry out a calibration which involves establishing the precise relationship between the torque applied to the sensor – input – and the electrical signal that it delivers – output.

The calibration of a torque meter has particularities compared to that of a dynamometer because the known forces must be applied through a lever arm, the error of which must also be perfectly mastered. The applied torque is usually pure torque with the use of effective decoupling. Therefore, the results of the calibration can only be used for measuring a pure torque. If the torque meter is used for calibration or verification of dynamometric wrenches, the calibration will:

- either be performed with the combined application of moments and transverse forces corresponding to those applied by the dynamometric wrench, or

- be supplemented by a specific test demonstrating the insensitivity of the torque meter to these transverse forces.

There is no international standard for the calibration of torque meters. However, a calibration guide has been established by the European Metrology Association EURAMET under the reference cg-14 / V.01 of July 2007 and available on the website http://www.euramet.org. International standard ISO 6789 gives a calibration procedure for dynamometric wrenches.

Upon request, we are also able to provide a torque sensor calibrated by a recognised and accredited test centre.

In this context, SENSY offers you its expertise for:

- choosing the right metrology to calibrate the torque sensor at the requested capacity;

- the choice of electronics: display, output cable, USB port, etc.

- the design, manufacturing and logistics of the necessary tools/accessories to ensure a precise and stable interface with the facilities at the test centre to apply torque.

Unfortunately, these interfaces often cost much more than the price of the sensor to be calibrated, which also applies to the price of calibration, especially as the request is often for a clockwise + anti-clockwise calibration.

When the customer chooses a sensor from the SENSY standard product range, he/she can benefit from SENSY’s interface tools which can be rented, thereby avoiding the manufacturing of new and expensive special tools.

However, if it is necessary to adapt the dimensions of the torque meter to the customer's own dimensions (in the case of existing machine equipment that the customer wants to instrument), our engineers will always ensure that priority is given to designing interfaces that can be adapted at a lower cost to existing tools. In this case, it is then possible to minimise the specific investment for the customer and to take advantage of connection pieces which already exist at SENSY.

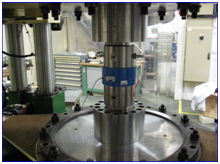

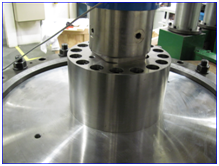

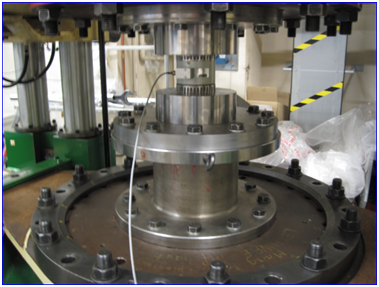

The pictures below illustrate this information.

Fastening rings often have a large diameter to minimise shearing and frictional forces on the bolting; the testing machine must have the necessary dimensions to cater for the largest capacities it may be required to test. In terms of torque, any friction between parts or any mechanical deformation resulting from the force in the coupling will induce errors in the transfer of the standard forces and distort the reference frame. This is why the couplings can be complex and expensive.

For medium and large capacities (from 2kNm to 1MNm), SENSY has developed – in collaboration with some test centres – a range of mechanical transfer accessories and a set of different fastening rings with tight tolerances.